(02) 8417 2190

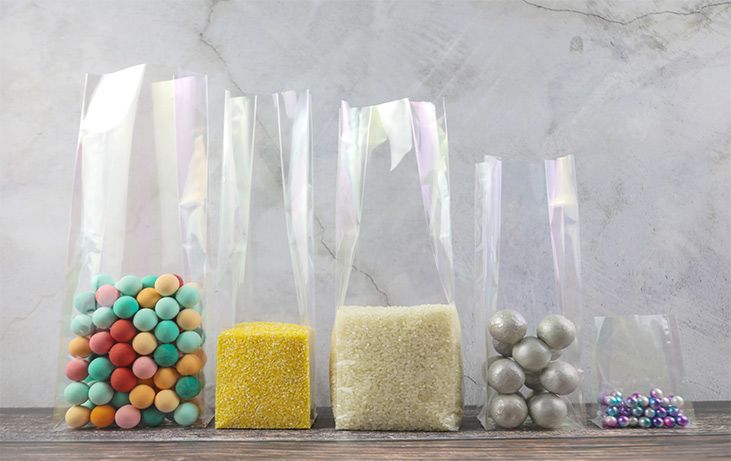

How to tell the difference between PP, OPP and BOPP bags

The BOPP bags and films are the most popular plastic packaging used by the food industry. BOPP bags can be coated, printed, laminated, and printed easily, making them ideal for packaging snacks, fresh produce, and confectioneries. OPP and PP bags, which can also be used for packaging, are also available on the market. Polypropylene, which is the main polymer used in the manufacture of all three bags, is the most common. PP stands to stand for Polypropylene. OPP stands out for Oriented Polypropylene and BOPP stands up for Biaxially Oriented Polypropylene. The style of fabrication is what makes them different.

Confused by some keywords? See our glossery index to learn more

Polypropylene is also known as polypropene, a semi-crystalline thermoplastic plastic polymer. It is tough and strong, and has a high impact resistance. Polypropylene is used in popular packaging items like standup pouches and ziplock pouches. It is hard to tell the difference between PP, OPP and BOPP plastics at first glance. Touching the OPP plastic feels more brittle than the PP plastic.

Understanding their usage in real-world objects is the best way to tell the difference between PP, OPP, and BOPP bags. Non-woven bags are made from Polypropylene bags, also known as PP bags. These bags are treated to make them more water- or moisture-absorbing. Some of the most common PP products include diapers, air filters and sanitary napkins. Thermal clothing is made from the same material. They provide a temperature barrier.

OPP bags are transparent in color and have a high tensile force. They can withstand high temperatures, but they will wrinkle if they are used too often. The same formula is used to make transparent adhesive tapes. These bags are tough to tear and are used for packaging leather products, clothing, and other items.

BOPP bags are clear polyethylene bags. The art of manufacturing is i.e. They are bi-axially oriented, which gives them a transparent appearance. This makes them ideal for branding with printing on their surfaces. The majority of BOPP bags are used for retail packaging. They are stronger and can carry more loads because of their biaxial orientation. BOPP bags are waterproof. They can protect your products from moisture for longer periods of time. These are the best cloth packaging options.

The Polypropylene derivatives i.e. The PP, OPP and BOPP are resistant against organic solvents, acids and alkalies. These are used widely in packaging industries where transport and storage under changing conditions is inevitable. They protect the product from dust and moisture, much like cling film. They can be recycled and have a lower carbon footprint. The PP, OPP and BOPP bags are a sustainable option from an environmental perspective.

Fast Direct Packaging also sells non-woven bags, vegetable and fruit crates.